The Origins of the First Mass-Market Tool Chest

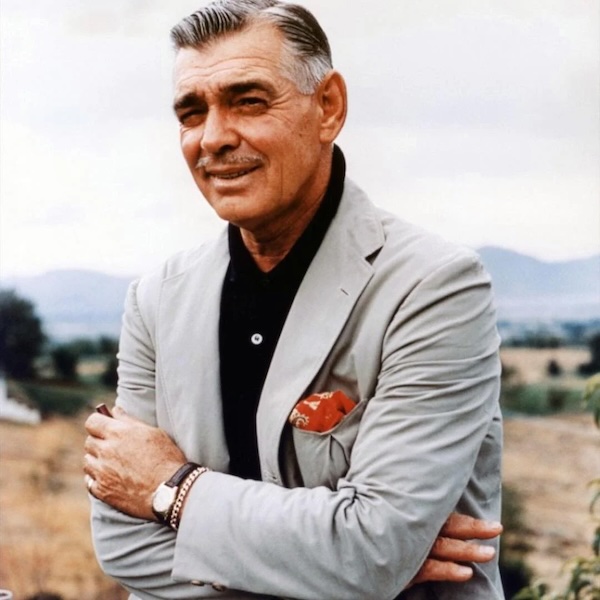

In 1901, a kid from Ohio named Harry Gerstner had had enough of high school and dropped out. He then started a four-year woodworking apprenticeship and trained to become a patternmaker.About a year into his patternmaking job, Gerstner became dissatisfied with the then-current state of tool storage. Tool chests existed, but they were exactly that—literal chests, which were large, heavy, and needed to be fished through to find the tool you wanted. During his evenings and weekends, Gerstner began developing a solution that would better suit him.He came up with a small chest of drawers that was much better-suited to hold the smaller, delicate tools used by patternmakers. Wrapped in leather, with brass fittings to protect the corners and a handle on top, it was durable and easy to move around the benchtop. The small drawers of gradated size made it easy to store and retrieve hand tools.Gerstner's co-workers took note of his invention, and he soon realized there was nothing else like it on the market. He shortly stopped working as a patternmaker and was soon running H. Gerstner & Sons, a business developed to manufacture and sell his toolchests. (Fun fact and early marketing spin: Gerstner had no sons, but three daughters. He named his new company to provide the illusion of history.)Gerstner's chests proved popular, and the design eventually evolved into what we today call a machinist's chest. Machinists became the de facto target market, as the chests were perfect for storing their calipers, gauge blocks and precision tools. The front of the case has a protective cover that slides down to reveal a felt-lined surface on which to temporarily place small parts or tools. Drawers can be pulled out and carried to the work. The diamond-shaped mirror is a bit of a curiosity; I'd heard that they were supposedly included in case the machinist got something stuck in their eye, while others have dismissed that as hogwash. This forum poster claims he reached out to the company (which still exists today) to inquire about the mirror's purpose, and received the following response:"The mirror was first installed in the early 1900's on some of the very earliest Gerstner chest designs. In those days, very few manufacturing and/or tool & die companies had indoor plumbing. In other words, there were few companies with lavatories (with wash basins and mirrors) for toolmakers and other factory workers to use to clean up at the end of the day."The 'mirror' mounted inside a Gerstner tool chest provided the wherewithal for the chest owner to check his appearance and comb his hair before heading home (or, perhaps, going in to ask the boss for a raise). At various times over the years, we have introduced a few tool chests without including a mirror. Interestingly enough, the feedback from customers has been, 'Without a mirror, the chest doesn't look like a Gerstner.' So . . .you may notice that virtually all new model Gerstners feature a 'mirror' inside the tip lid."That explanation sounds fishy as hell to me—and why is "mirror" occasionally placed in quotes?—but what do I know, I'm not a detective.In any case Gerstner had found an untapped market, and multiple competitors cropped up; by the end of the 1910s, there were about 15 companies making a similar chest. H. Gerstner & Sons outlasted them throughout the century, and had no competitors left by the mid-1960s.Since their launch in 1906, Gerstner priced the chests at roughly a week's wages for a skilled tradesperson ($6 in 1906) and kept that ratio steady throughout the 20th century. Today, they still sell a model, the Classic Chest, that is remarkably close to the 20th-century design. (The most notable difference is that the single top handle has been replaced by two side handles.) It's available in the original Oak as well as fancier woods like Walnut and Cherry. However, the prices of the Classic today is $1,695. The Bureau of Labor Statistics has the median salary of a machinist today at $56,150, which would make a week's wages about $1,080. That doesn't place the chest completely out of reach of a machinist, but I'm guessing today's customers are more likely filling the drawers with knife collections and RC car parts.

In 1901, a kid from Ohio named Harry Gerstner had had enough of high school and dropped out. He then started a four-year woodworking apprenticeship and trained to become a patternmaker.

About a year into his patternmaking job, Gerstner became dissatisfied with the then-current state of tool storage. Tool chests existed, but they were exactly that—literal chests, which were large, heavy, and needed to be fished through to find the tool you wanted. During his evenings and weekends, Gerstner began developing a solution that would better suit him.

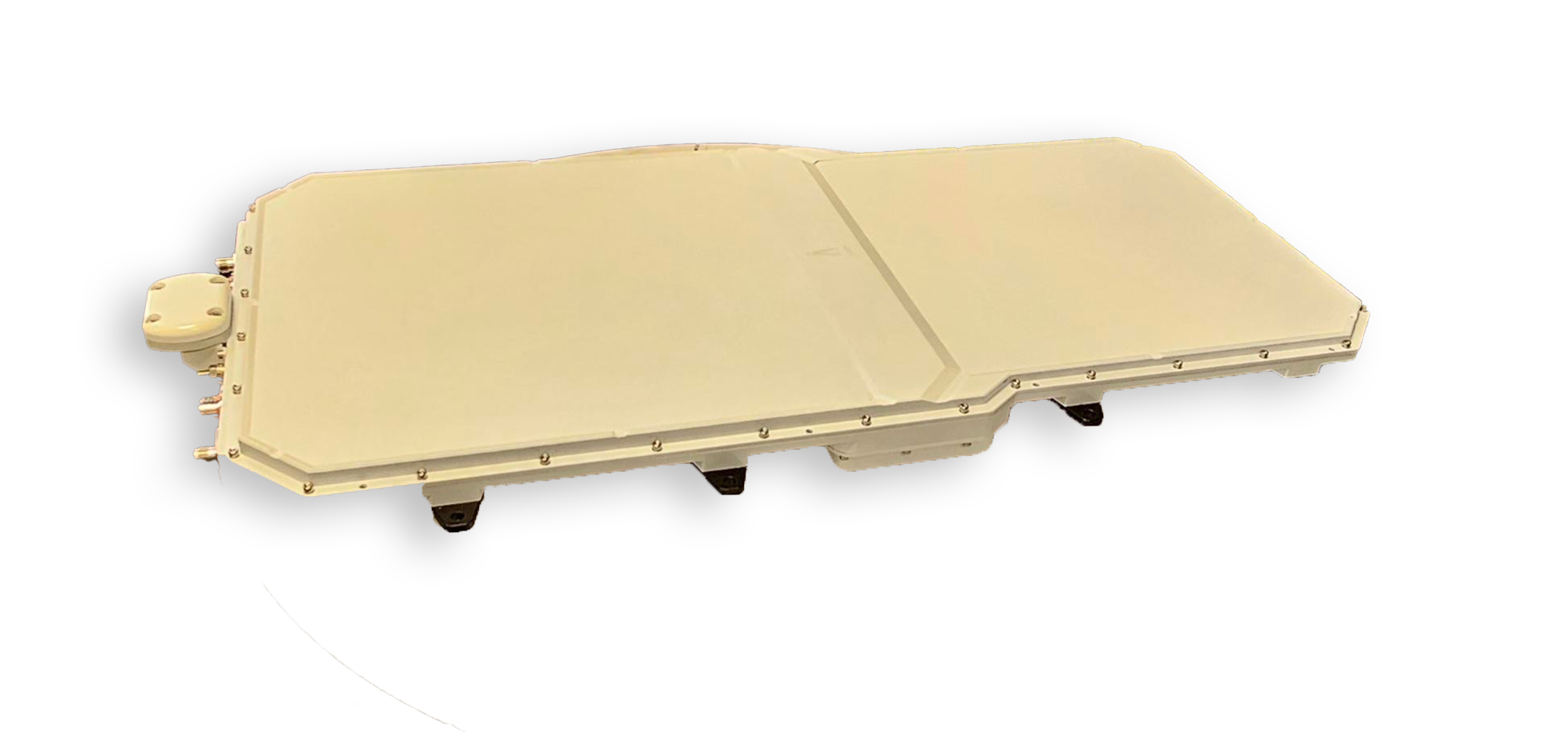

He came up with a small chest of drawers that was much better-suited to hold the smaller, delicate tools used by patternmakers. Wrapped in leather, with brass fittings to protect the corners and a handle on top, it was durable and easy to move around the benchtop. The small drawers of gradated size made it easy to store and retrieve hand tools.

Gerstner's co-workers took note of his invention, and he soon realized there was nothing else like it on the market. He shortly stopped working as a patternmaker and was soon running H. Gerstner & Sons, a business developed to manufacture and sell his toolchests. (Fun fact and early marketing spin: Gerstner had no sons, but three daughters. He named his new company to provide the illusion of history.)

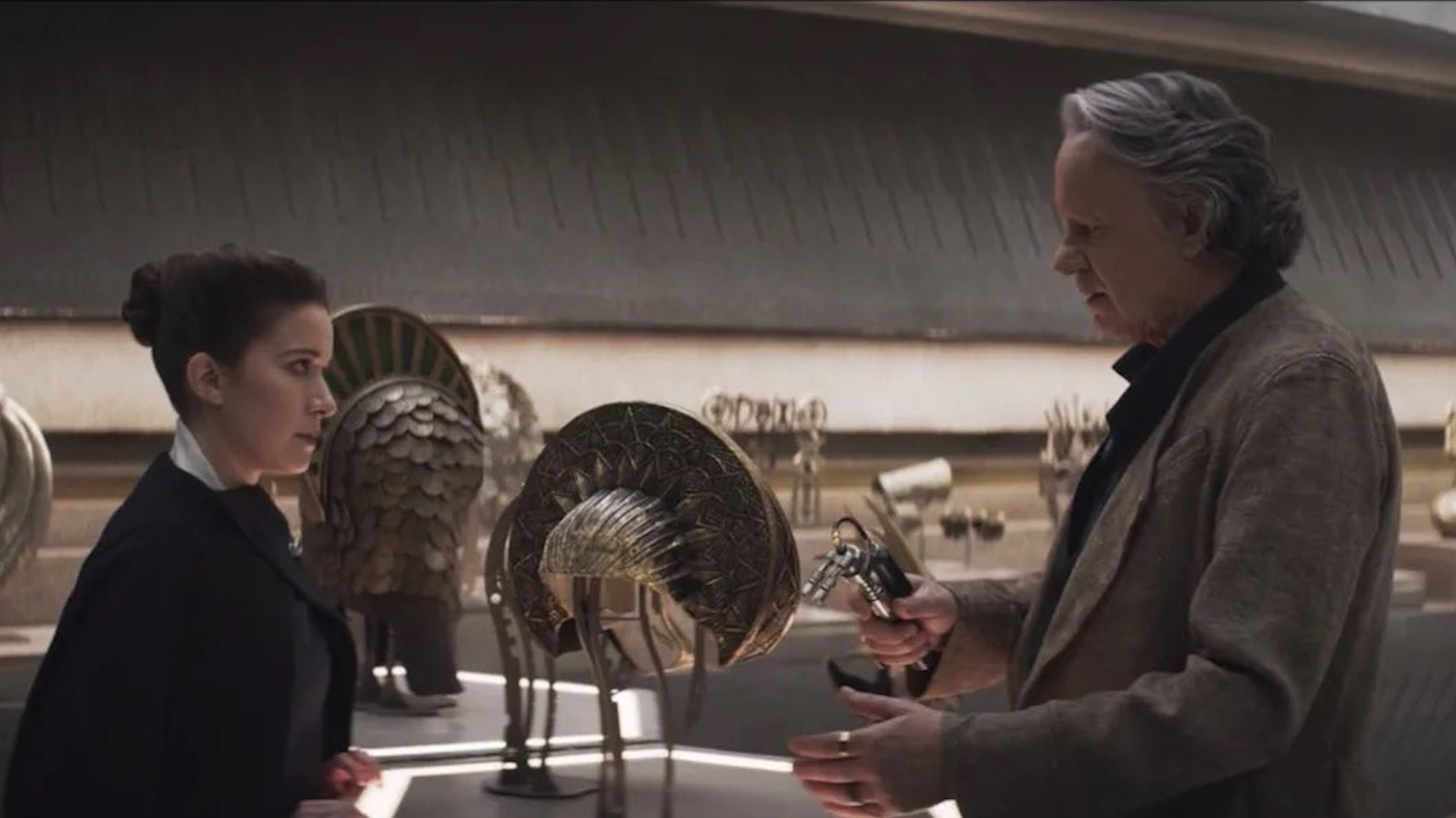

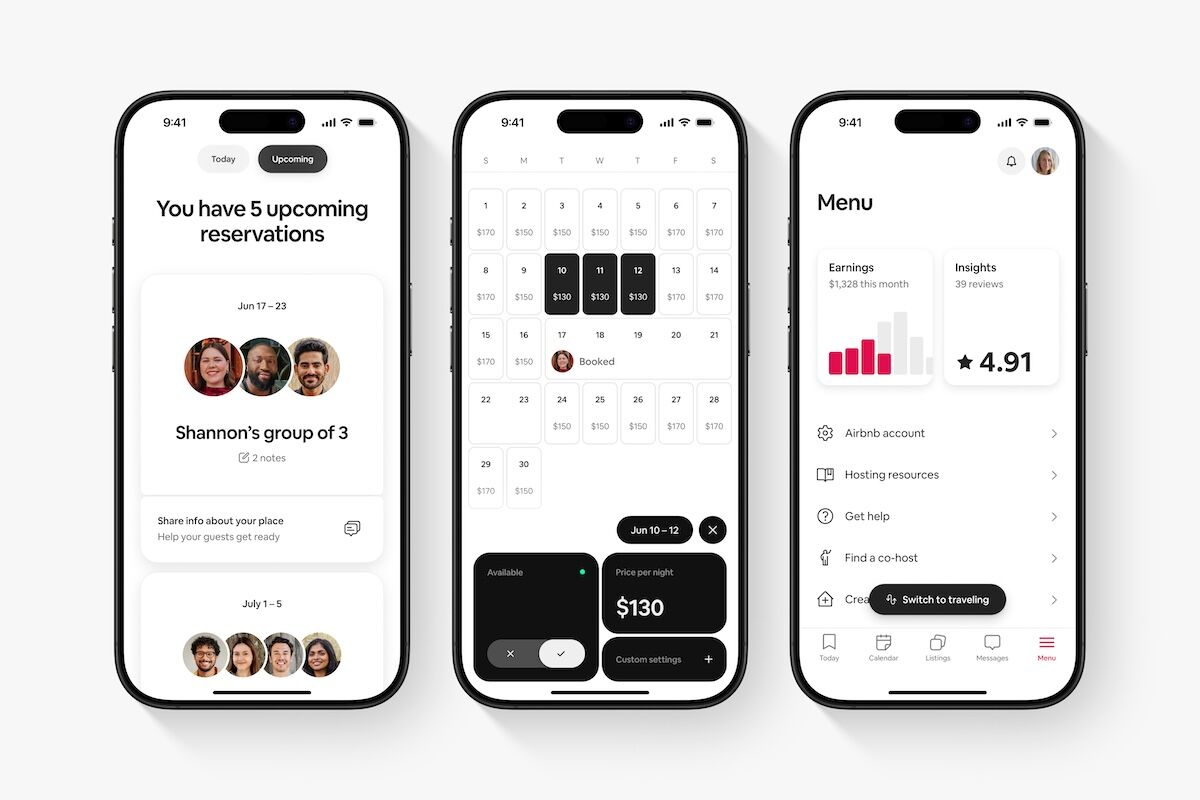

Gerstner's chests proved popular, and the design eventually evolved into what we today call a machinist's chest. Machinists became the de facto target market, as the chests were perfect for storing their calipers, gauge blocks and precision tools.

The front of the case has a protective cover that slides down to reveal a felt-lined surface on which to temporarily place small parts or tools. Drawers can be pulled out and carried to the work.

The diamond-shaped mirror is a bit of a curiosity; I'd heard that they were supposedly included in case the machinist got something stuck in their eye, while others have dismissed that as hogwash. This forum poster claims he reached out to the company (which still exists today) to inquire about the mirror's purpose, and received the following response:

"The mirror was first installed in the early 1900's on some of the very earliest Gerstner chest designs. In those days, very few manufacturing and/or tool & die companies had indoor plumbing. In other words, there were few companies with lavatories (with wash basins and mirrors) for toolmakers and other factory workers to use to clean up at the end of the day.

"The 'mirror' mounted inside a Gerstner tool chest provided the wherewithal for the chest owner to check his appearance and comb his hair before heading home (or, perhaps, going in to ask the boss for a raise). At various times over the years, we have introduced a few tool chests without including a mirror. Interestingly enough, the feedback from customers has been, 'Without a mirror, the chest doesn't look like a Gerstner.' So . . .you may notice that virtually all new model Gerstners feature a 'mirror' inside the tip lid."

That explanation sounds fishy as hell to me—and why is "mirror" occasionally placed in quotes?—but what do I know, I'm not a detective.

In any case Gerstner had found an untapped market, and multiple competitors cropped up; by the end of the 1910s, there were about 15 companies making a similar chest. H. Gerstner & Sons outlasted them throughout the century, and had no competitors left by the mid-1960s.

Since their launch in 1906, Gerstner priced the chests at roughly a week's wages for a skilled tradesperson ($6 in 1906) and kept that ratio steady throughout the 20th century. Today, they still sell a model, the Classic Chest, that is remarkably close to the 20th-century design. (The most notable difference is that the single top handle has been replaced by two side handles.) It's available in the original Oak as well as fancier woods like Walnut and Cherry.

However, the prices of the Classic today is $1,695. The Bureau of Labor Statistics has the median salary of a machinist today at $56,150, which would make a week's wages about $1,080. That doesn't place the chest completely out of reach of a machinist, but I'm guessing today's customers are more likely filling the drawers with knife collections and RC car parts.

![Odd Couplings [BODY OF EVIDENCE & DAMAGE]](http://2.bp.blogspot.com/_0uQUF0LK0NQ/Svr4k4n2lbI/AAAAAAAAAG8/sKnt2TuDgt4/s320/MADONNA++-++WILLEM+DaFOE.bmp)

![Don’t Look Back [short story]](https://jonathanrosenbaum.net/wp-content/uploads/2011/11/friedrich-mountain-landscape1-300x232.jpg)