How Metal Objects Used to First be Made Out of Wood

A lot of different trades powered the Industrial Revolution. As that movement motored into the 20th Century, a particularly crucial one was the patternmaker. When you hear "patternmaker" today you probably picture a seamstress and garments. But the patternmaker I'm talking about was someone that 20th-century engineers, and industrial designer of 3D objects, would have collaborated with. In order to produce cast metal parts, you first need to create a mold. The only viable option, for much of the 20th century, was to start with wood. Manufacturers hired highly skilled woodworkers to precisely carve the first instance of the intended part. This wooden pattern was then pressed into a box filled with sand to create the mold. Patternmakers were called on to carve machine parts, sewing machine bodies, bells, fire hydrants, sewer grates, manhole covers, pipe fittings and even automotive parts like differentials and engine blocks. Though patternmakers who work with wood are hard to find today, the profession existed well throughout the 20th century. If your'e interested in learning more: Joel Moskowitz, the founder of Brooklyn-based Tools for Working Wood, is a mechanical engineer by training. His first job was developing power tools for Black & Decker in the 1980s, and in this blog post he describes the process of working with a patternmaker to develop a vacuum attachment.

A lot of different trades powered the Industrial Revolution. As that movement motored into the 20th Century, a particularly crucial one was the patternmaker.

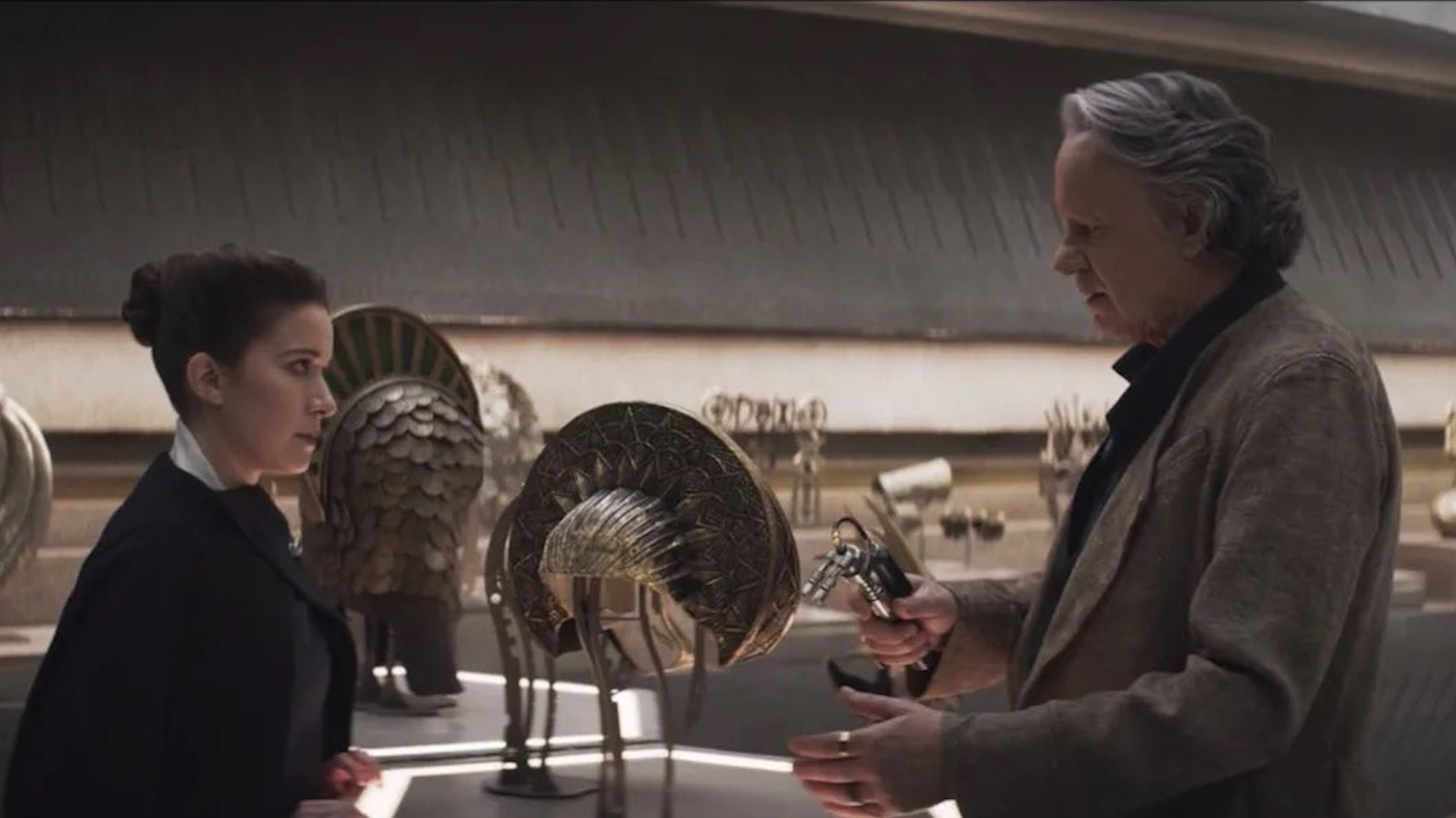

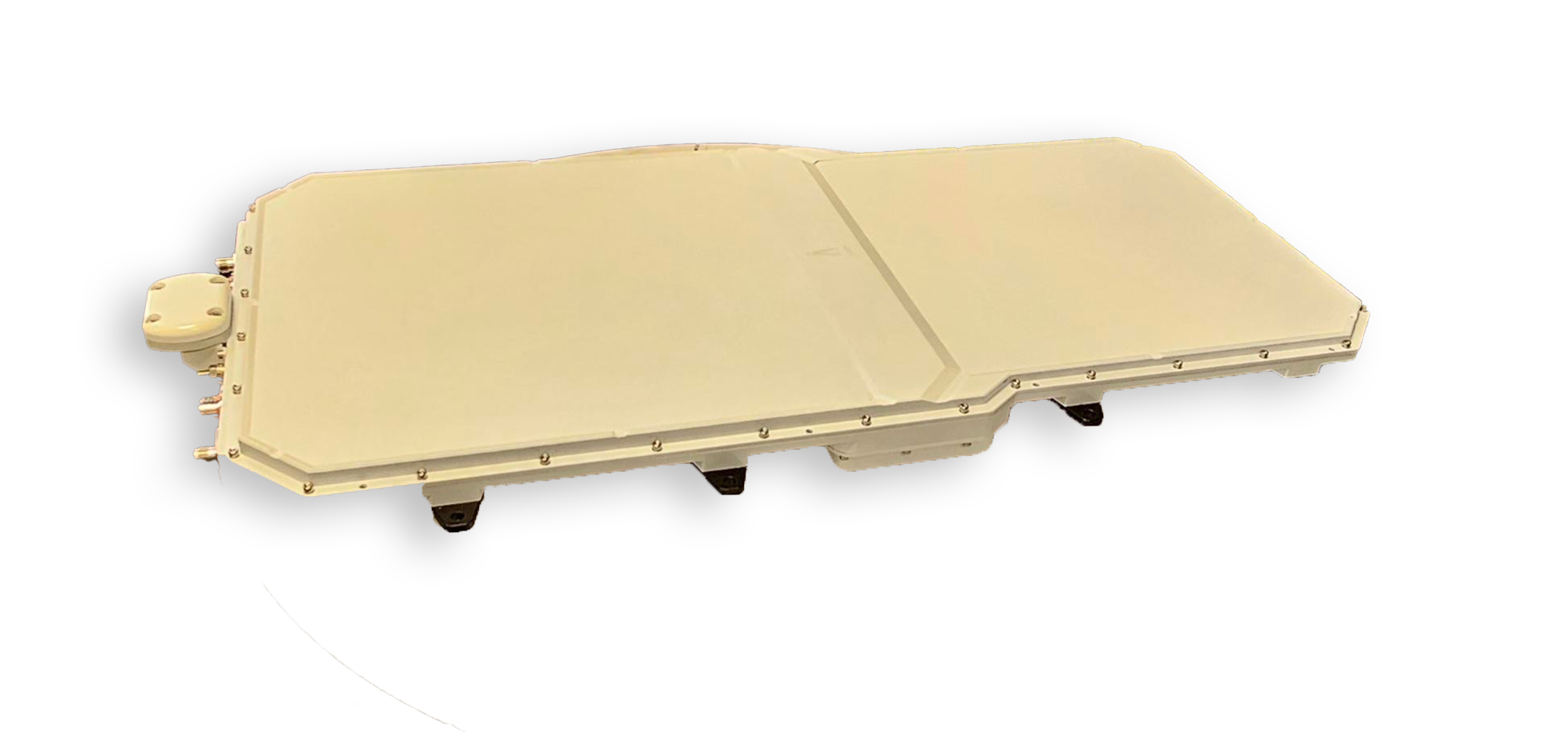

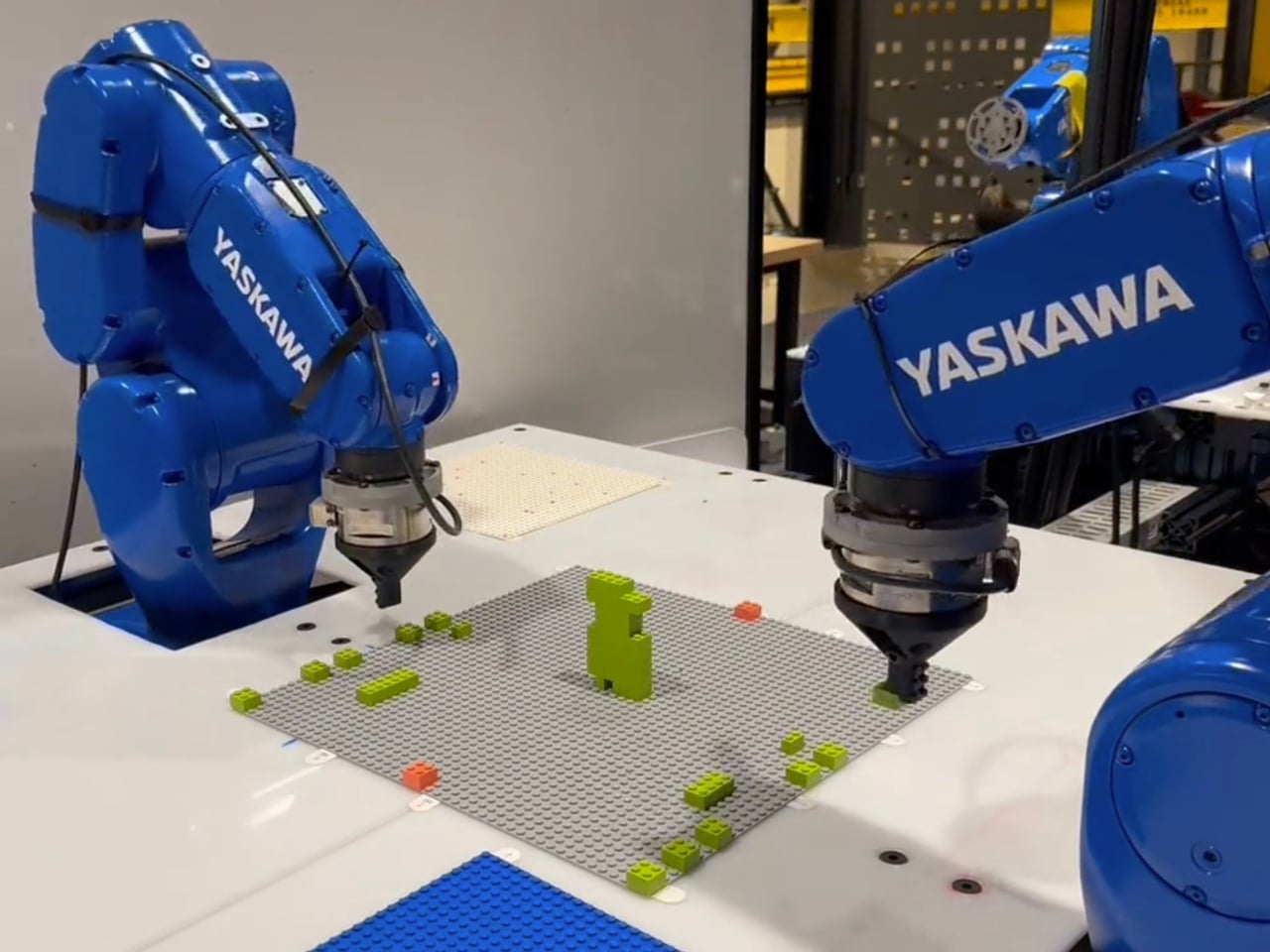

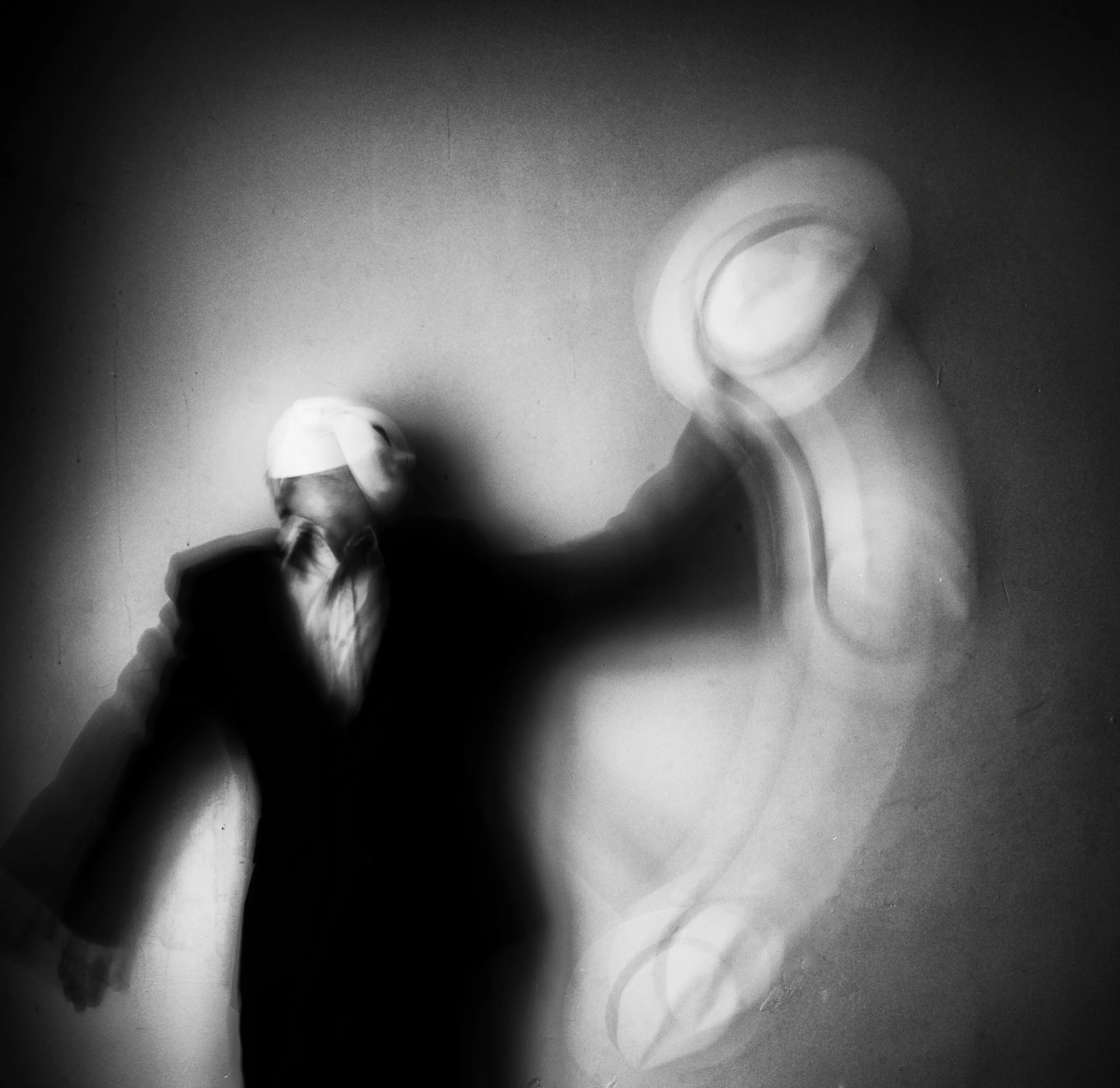

When you hear "patternmaker" today you probably picture a seamstress and garments. But the patternmaker I'm talking about was someone that 20th-century engineers, and industrial designer of 3D objects, would have collaborated with. In order to produce cast metal parts, you first need to create a mold. The only viable option, for much of the 20th century, was to start with wood. Manufacturers hired highly skilled woodworkers to precisely carve the first instance of the intended part. This wooden pattern was then pressed into a box filled with sand to create the mold.

Patternmakers were called on to carve machine parts, sewing machine bodies, bells, fire hydrants, sewer grates, manhole covers, pipe fittings and even automotive parts like differentials and engine blocks.

Though patternmakers who work with wood are hard to find today, the profession existed well throughout the 20th century.

If your'e interested in learning more: Joel Moskowitz, the founder of Brooklyn-based Tools for Working Wood, is a mechanical engineer by training. His first job was developing power tools for Black & Decker in the 1980s, and in this blog post he describes the process of working with a patternmaker to develop a vacuum attachment.

![Odd Couplings [BODY OF EVIDENCE & DAMAGE]](http://2.bp.blogspot.com/_0uQUF0LK0NQ/Svr4k4n2lbI/AAAAAAAAAG8/sKnt2TuDgt4/s320/MADONNA++-++WILLEM+DaFOE.bmp)

![Don’t Look Back [short story]](https://jonathanrosenbaum.net/wp-content/uploads/2011/11/friedrich-mountain-landscape1-300x232.jpg)