Design Opportunity: Create a Better Portable Tufting Frame

What the drafting board is to draftspeople, and the easel is to painters, the tufting frame is to tufters. Tufting is sort of a cross between sewing and embroidery. A backing material like burlap, linen or polyester is stretched over a frame and held in place with nails or tack strips.Image: Emilymaayy, CC BY-SA 4.0 A pattern is drawn onto the fabric (or sometimes projected and traced). Working from the back side of the backing material, the tufter then punches yarn through it, creating a loop or pile on the front. Each individual pile is essentially the tufter's pixel, and by following the pattern they "draw" an image visible from the front of the backing material. The tool traditionally used was a tufting needle…Image: Auckland Museum, CC BY 4.0 …but today motorized tufting guns are commonly used.Image: KnowledgeBySean, CC BY-SA 4.0 Dedicated rug-making shops have permanent tufting frames sized to their preferences. But for the hobbyist, a tufting frame, like the drafting table, requires a commitment of space. When not in use, a large rectangular frame on legs is not easy to store within the average home. Thus portable tufting frames are on the market, like this one by a tufting startup called ClawLab.The aluminum ClawLab frame can be clamped to a tabletop. With a traditional wooden tufting frame, the backing material is held in place by nails or tack strips. ClawLab instead uses a system of velcro and rods that rotate to draw the fabric around it and hold it taut. It creates, the company reckons, the perfect worksurface on which to use the tufting gun that they also developed. Here's how the system is set up and used:I will say, the vertical orientation doesn't look terribly ergonomic if you're using it in a standing position. I don't know how big the market is, but there is an opportunity here for better design.

What the drafting board is to draftspeople, and the easel is to painters, the tufting frame is to tufters.

Tufting is sort of a cross between sewing and embroidery. A backing material like burlap, linen or polyester is stretched over a frame and held in place with nails or tack strips.

Image: Emilymaayy, CC BY-SA 4.0

Image: Emilymaayy, CC BY-SA 4.0

A pattern is drawn onto the fabric (or sometimes projected and traced). Working from the back side of the backing material, the tufter then punches yarn through it, creating a loop or pile on the front. Each individual pile is essentially the tufter's pixel, and by following the pattern they "draw" an image visible from the front of the backing material.

The tool traditionally used was a tufting needle…

Image: Auckland Museum, CC BY 4.0

Image: Auckland Museum, CC BY 4.0

…but today motorized tufting guns are commonly used.

Image: KnowledgeBySean, CC BY-SA 4.0

Image: KnowledgeBySean, CC BY-SA 4.0

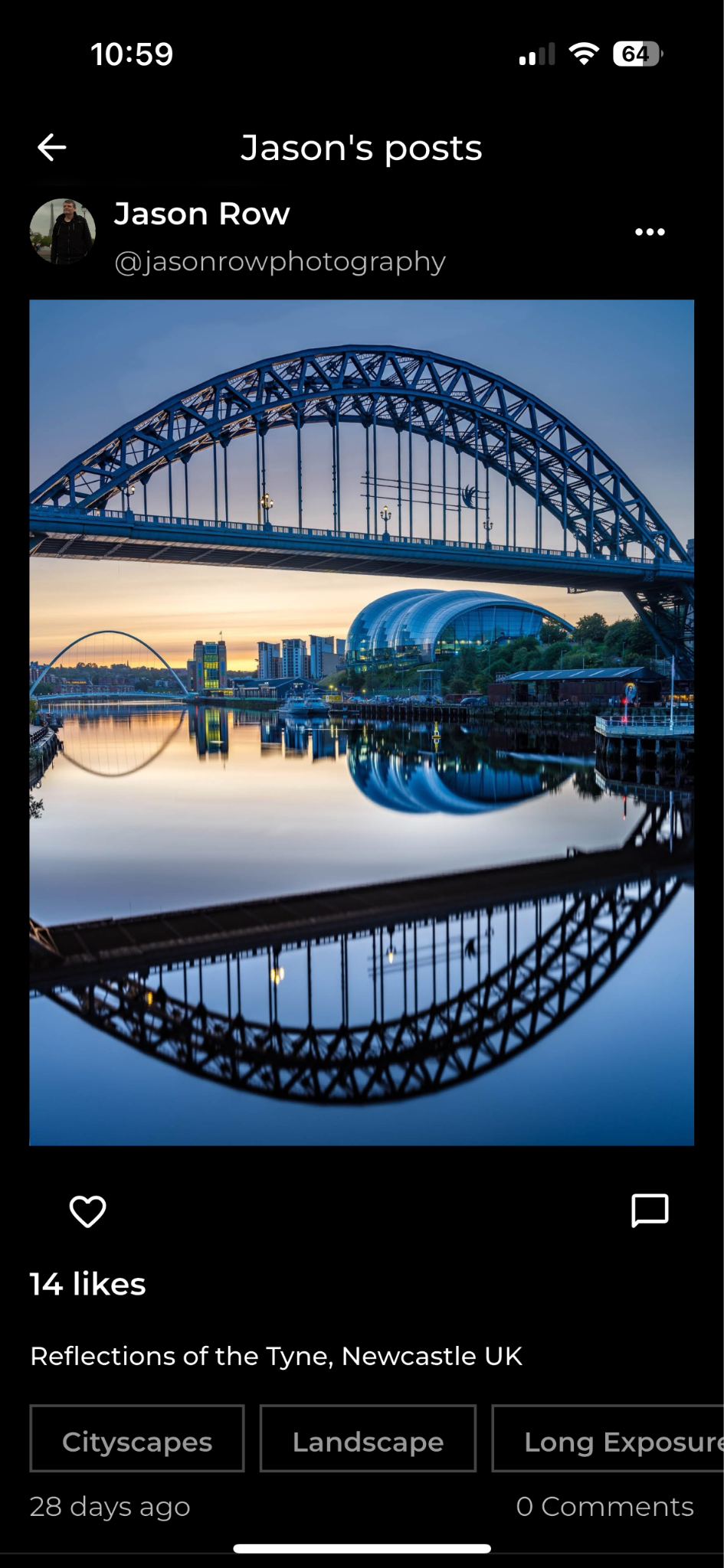

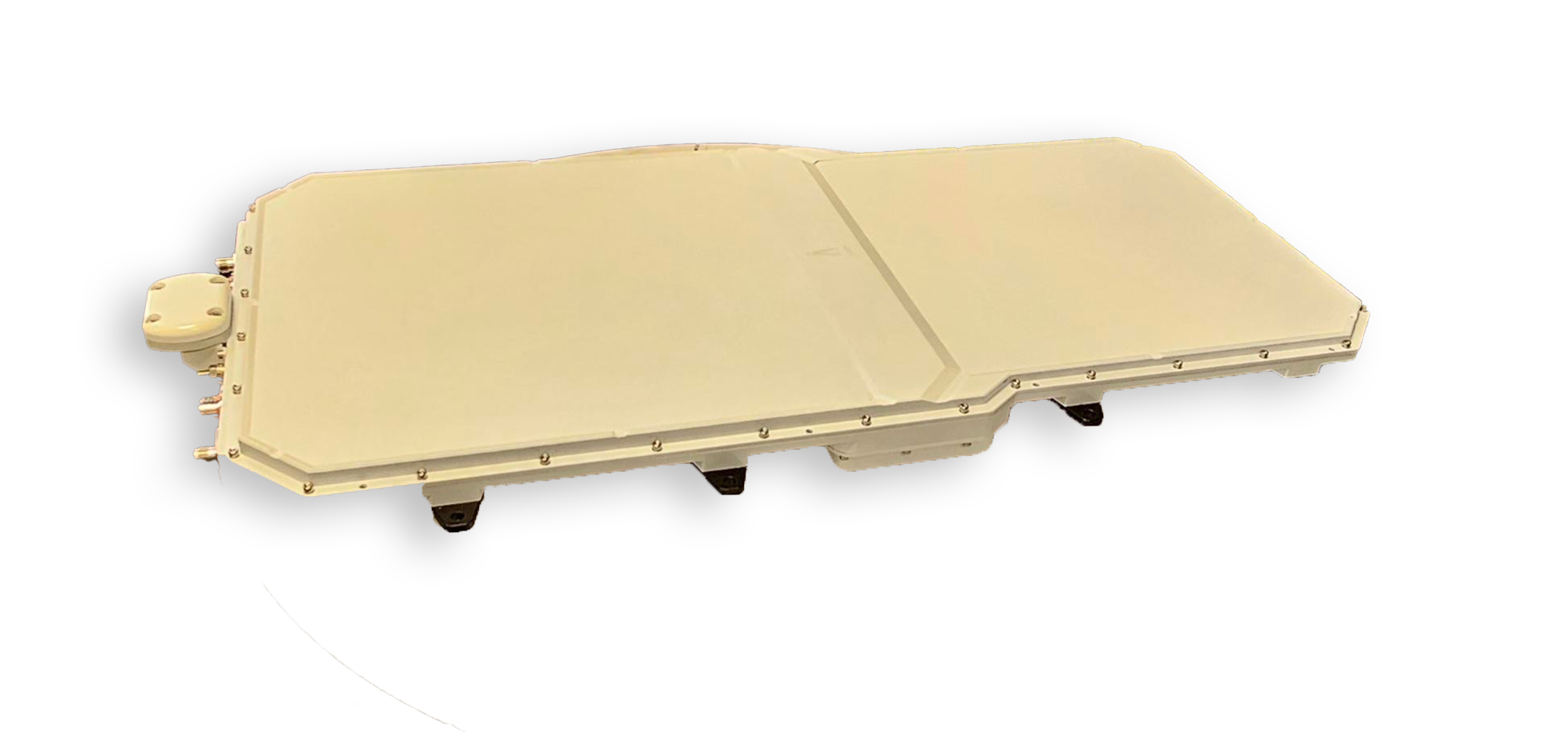

Dedicated rug-making shops have permanent tufting frames sized to their preferences. But for the hobbyist, a tufting frame, like the drafting table, requires a commitment of space. When not in use, a large rectangular frame on legs is not easy to store within the average home. Thus portable tufting frames are on the market, like this one by a tufting startup called ClawLab.

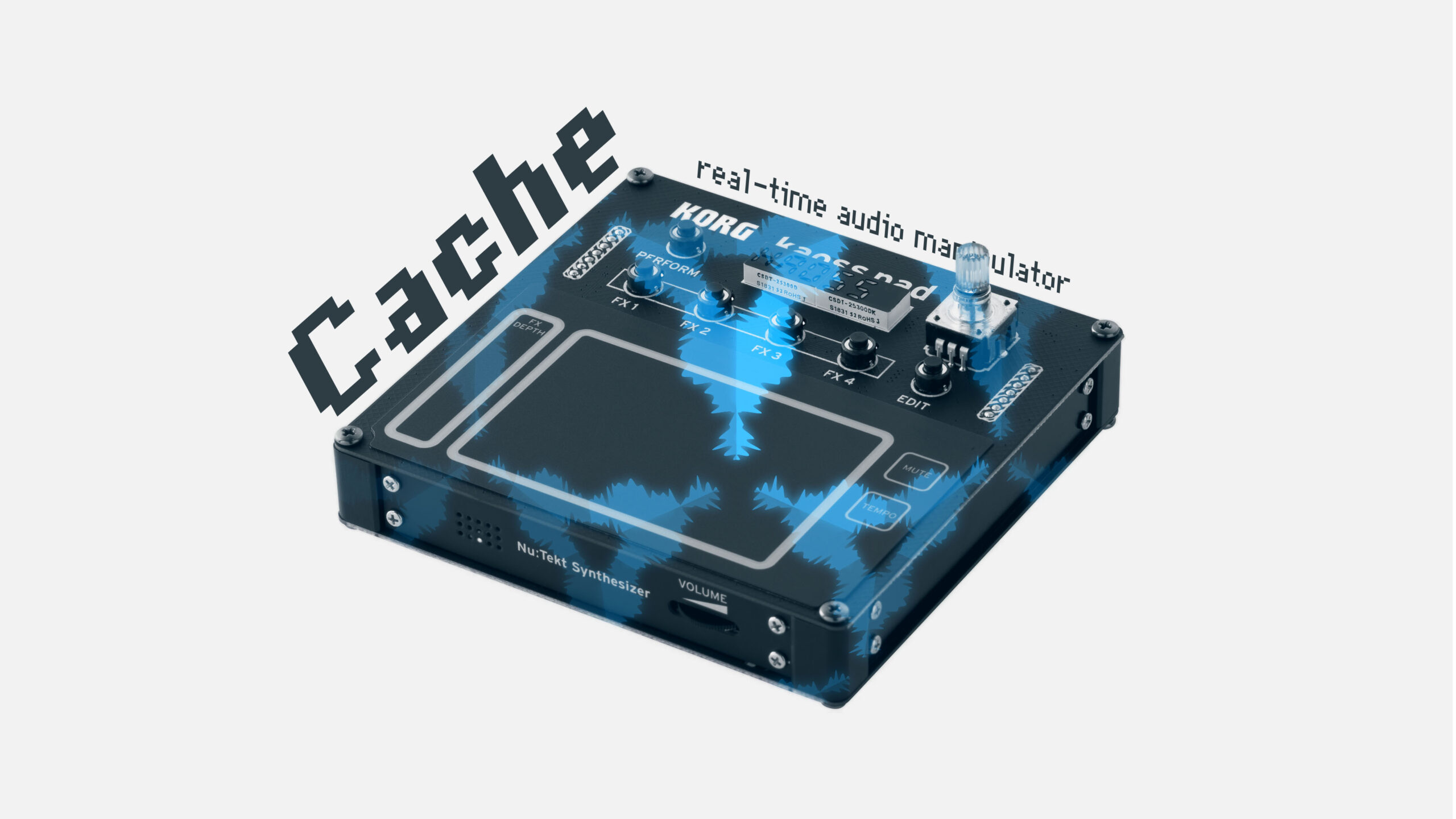

The aluminum ClawLab frame can be clamped to a tabletop.

With a traditional wooden tufting frame, the backing material is held in place by nails or tack strips. ClawLab instead uses a system of velcro and rods that rotate to draw the fabric around it and hold it taut. It creates, the company reckons, the perfect worksurface on which to use the tufting gun that they also developed.

With a traditional wooden tufting frame, the backing material is held in place by nails or tack strips. ClawLab instead uses a system of velcro and rods that rotate to draw the fabric around it and hold it taut. It creates, the company reckons, the perfect worksurface on which to use the tufting gun that they also developed.

Here's how the system is set up and used:

I will say, the vertical orientation doesn't look terribly ergonomic if you're using it in a standing position. I don't know how big the market is, but there is an opportunity here for better design.

![‘Blood, Sweat, Tears… and More Blood’ Documents the Making of Indie Horror-Comedy ‘Cannibal Comedian’ [Trailer]](https://bloody-disgusting.com/wp-content/uploads/2025/05/cannibalcomedian-mask.jpg)

![Pieces of Masterpieces [MEDEA & SUNDAY]](https://jonathanrosenbaum.net/wp-content/uploads/2011/04/medea.jpg)

![American Airlines Offering 5,000-Mile Main Cabin Awards—Because Coach Seats Aren’t Selling [Roundup]](https://boardingarea.com/wp-content/uploads/2025/05/32387544a799e8261f927c3eb9f4934a-scaled.jpg?#)

![[Expired] 100K Chase Sapphire Preferred Card offer](https://frequentmiler.com/wp-content/uploads/2025/04/100K-points-offer.jpg?#)

![Air Traffic Controller Claps Back At United CEO Scott Kirby: ‘You’re The Problem At Newark’ [Roundup]](https://viewfromthewing.com/wp-content/uploads/2025/05/scott-kirby-on-stage.jpg?#)

-Marathon-Gameplay-Overview-Trailer-00-04-50.png?width=1920&height=1920&fit=bounds&quality=70&format=jpg&auto=webp#)

![[Podcast] Making Brands Relevant: How to Connect Culture, Creativity & Commerce with Cyril Louis](https://justcreative.com/wp-content/uploads/2025/05/cyril-lewis-podcast-29.png)