Creality Falcon A1: The $499 Smart Laser Cutter That Recognizes Materials Before Cutting Them

Creality Falcon A1: The $499 Smart Laser Cutter That Recognizes Materials Before Cutting ThemThe first time I used a laser cutter was in my university’s fabrication lab. It felt like operating a small nuclear reactor – there was...

The first time I used a laser cutter was in my university’s fabrication lab. It felt like operating a small nuclear reactor – there was a mandatory safety course, supervision requirements, and enough warning labels to make me genuinely concerned about spontaneous combustion. For years, laser cutting remained this mystical, slightly terrifying technology that lived behind institutional walls. Fast forward to today, and I’m looking at Creality’s Falcon A1 sitting on a desk, looking about as threatening as a microwave oven – albeit one that can engrave Batman logos onto leather wallets.

Creality, the company that helped democratize 3D printing with its affordable Ender series, is now attempting the same revolution with laser cutting technology. The Falcon A1 is their enclosed 10W laser engraver and cutter that promises to bring professional-grade capabilities to your desktop without requiring a fire marshal on standby.

Designer: Creality

Click Here to Buy Now: $519 $549 ($30 off, use coupon code “Yanko”). Hurry, deal ends in 48-hours!

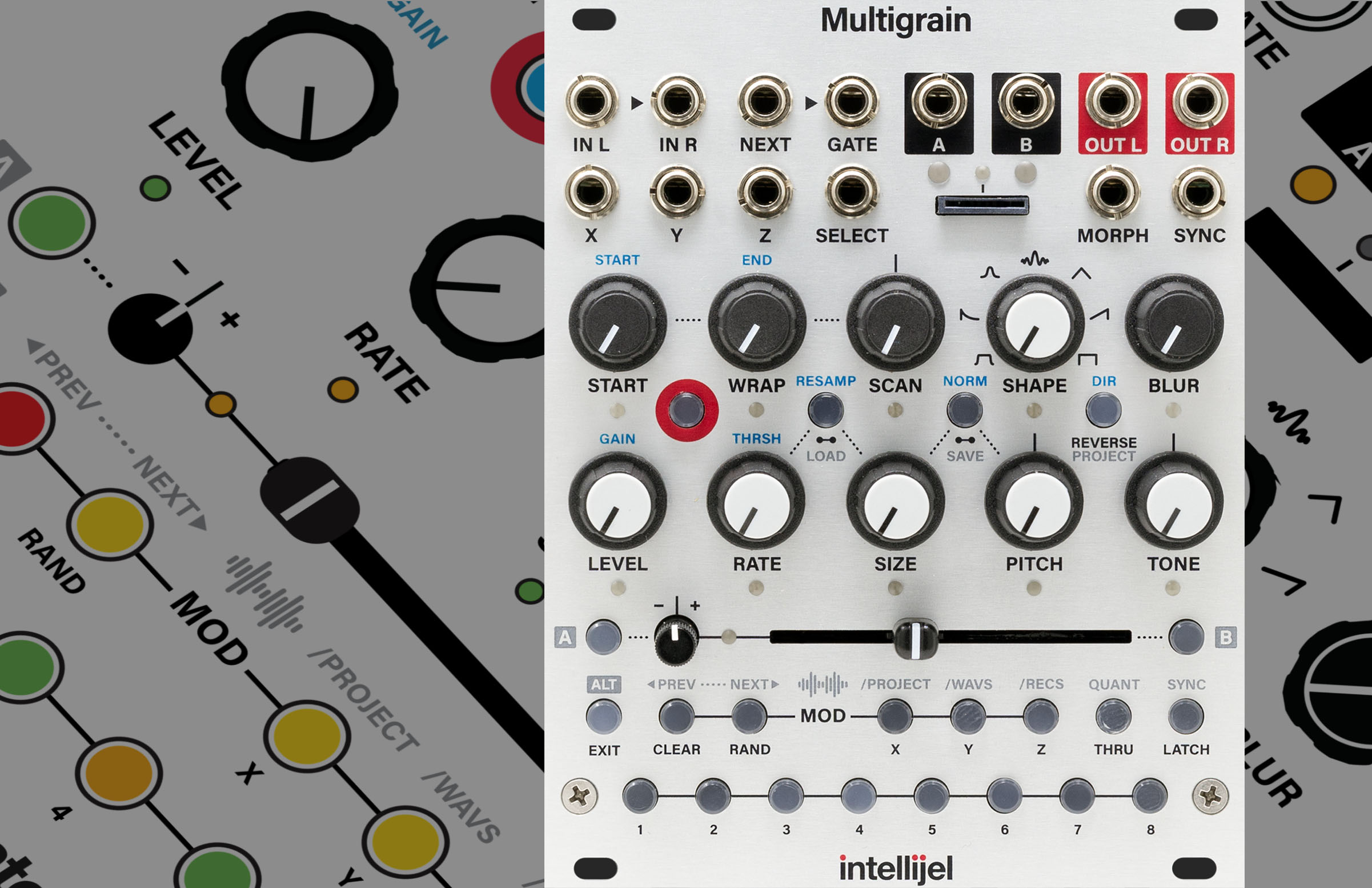

AI-Powered Material Recognition: The End of Parameter Guesswork

If you’ve ever used a laser cutter, you know the anxiety of setting power and speed parameters. Too much power and you burn through your material; too little and you barely make a mark. The Falcon A1 tackles this common frustration with its innovative material recognition system.

The machine features a built-in QR code system that automatically detects Creality’s specially marked materials. When you place one of these materials in the workspace, the Falcon A1 identifies it and automatically loads the optimal cutting or engraving parameters. No more guesswork, no more test cuts, and no more wasted materials.

For beginners, this feature is transformative. It removes one of the steepest parts of the learning curve and allows new users to achieve professional-quality results from their very first project. For experienced users, it saves valuable time that would otherwise be spent on parameter testing and adjustment. In the long run, it streamlines work, doing for materials what barcodes do for items in a grocery store.

The system currently works with Creality’s range of compatible materials, which includes various types of wood, acrylic, leather, and more. Each comes with its own QR code that the machine scans to identify the exact material type and thickness. While this does create some ecosystem lock-in, the convenience factor is substantial enough that many users will find it worthwhile.

Even when working with non-Creality materials, the software includes a comprehensive material library with recommended settings that serve as excellent starting points, significantly reducing the trial-and-error process. Just note that highly reflective materials like mirrored metals are off-limits – physics still has some rules that even Creality can’t bend.

Safety First, Intimidation Last

The most striking thing about the Falcon A1 is its fully enclosed design, which for Creality’s first-ever laser-cutting product, really looks like a polished consumer gadget rather than a trial device. The black and orange aesthetic is distinctly Creality, with a transparent viewing window that lets you watch the laser do its magic while blocking harmful light. The enclosure contains smoke, prevents accidental exposure to the beam, and includes multiple safety mechanisms, including magnetic door sensors that automatically pause operation when opened.

With its Class 1 safety certification, you can actually skip the safety glasses – a refreshing change from the institutional paranoia I’ve experienced around industrial laser systems. There’s even an emergency stop button just in case you want to quickly pause a job for whatever reason.

Power in a Small Package

Powering the Falcon A1 is a 10W optical output laser module. Translation for the non-technical: this thing can cut through 9.6mm acrylic and 5mm wood in a single pass. For engraving, it handles everything from wood and leather to glass, stone, and anodized aluminum with 0.01mm precision.

The 381 x 305mm working area hits the sweet spot for hobbyist and small business use – large enough for meaningful projects but compact enough to fit on a desk. The machine itself measures 567 × 468 × 196mm and weighs a manageable 20 pounds (9.1 kg), making it apartment-friendly (though your roommates might question the burning smell when you’re cutting wood). The CoreXY motion system is no slouch either, zipping along at speeds up to 600mm/s – fast enough to make you question whether you’re watching a time-lapse video.

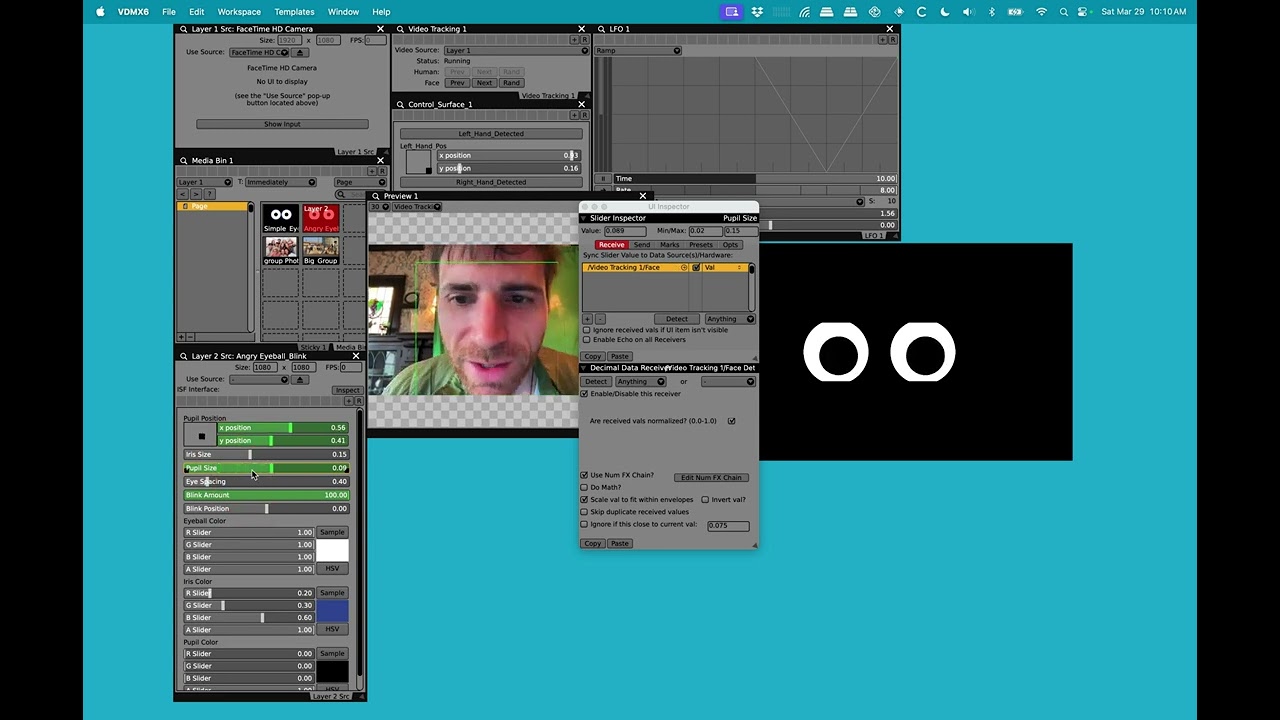

Smart Camera: Your Digital Third Eye

Unlike traditional laser cutters where positioning is a game of mathematical guesswork, the Falcon A1 provides a full-frame view of your workspace in real-time thanks to its pre-calibrated high-definition camera system that transforms how you interact with your projects. The camera system creates what Creality calls a “what you see is what you get” experience. You can literally drag and drop your design onto the exact location where you want it on your material, with the camera showing you precisely how it will be positioned. This eliminates the frustrating trial-and-error approach that wastes materials and time.

Perhaps even more impressive is the camera’s auto-positioning and batch-filling capabilities. If you’re creating multiple identical items (think business cards, coasters, or jewelry pieces), the system can automatically detect available space on your material and populate it with copies of your design. This feature alone can dramatically increase production efficiency for small businesses or high-volume hobbyists. The camera also serves as a safety feature, allowing you to monitor the cutting process remotely through the software interface. If anything looks amiss, you can pause or stop the job without opening the enclosure and interrupting the protective environment. That said, some users report needing to manually calibrate the camera despite its “pre-calibrated” status – a minor inconvenience in an otherwise slick system.

Smart Features for Newbie Users

What truly separates the Falcon A1 from industrial machines is its user-friendly approach. Beyond the camera system and material recognition, the accompanying Falcon Design Space software lets you import designs in common formats like SVG, JPG, PNG, and DXF, with the ability to adjust parameters for different materials.

The machine connects via Wi-Fi, USB, or through the cloud, allowing you to send projects from virtually anywhere – though I wouldn’t recommend remote laser cutting unless you enjoy living dangerously. The integrated smoke extraction system routes fumes outside through an exhaust tube, though you’ll still want to place it near a window or ventilated area. No laser cutter can completely eliminate the distinctive smell of vaporized materials, after all.

Democratizing Digital Fabrication

At $499-$550, the Falcon A1 occupies an interesting middle ground in the market. It’s significantly more capable than the sub-$300 open-frame laser engravers flooding Amazon, but far more affordable than professional systems from companies like Epilog or Trotec that start at several thousand dollars. This positioning makes it perfect for several user groups: makers looking to add laser cutting to their arsenal, small businesses wanting to produce custom products, and educational settings where safety is paramount but budgets are tight.

I can easily imagine Etsy sellers using this to create custom wooden signs, jewelry makers cutting intricate acrylic pieces, or hobbyists finally being able to create those precise model parts that scissors and X-Acto knives simply can’t manage.

Editor’s Take: Close to a Cutting-Edge Revolution

What excites me most about the Falcon A1 isn’t just what it can do, but what it represents. Just as consumer 3D printers transformed from expensive curiosities to mainstream tools, laser cutters are following the same trajectory – just a few years behind.

The Falcon A1 isn’t perfect – serious power users will eventually want more cutting capability, and the software, while functional, has been reported to have some calibration issues and a learning curve for beginners. But it succeeds brilliantly at its primary mission: making laser cutting accessible, safe, and approachable.

For many creators, this machine will be their first step into laser cutting – a technology that was previously out of reach due to cost, space requirements, or safety concerns. That’s genuinely exciting, and I can’t wait to see what people create with tools like this.

If you’ve been curious about laser cutting but intimidated by the complexity, cost, or safety concerns, the Falcon A1 might be the machine that finally lets you add “laser wizard” to your maker resume. Just remember to open a window – even the smartest laser cutter can’t eliminate the distinctive smell of your creative ambitions accidentally triggering a smoke detector!

Click Here to Buy Now: $519 $549 ($30 off, use coupon code “Yanko”). Hurry, deal ends in 48-hours!

The post Creality Falcon A1: The $499 Smart Laser Cutter That Recognizes Materials Before Cutting Them first appeared on Yanko Design.

![Leaked: Elon Musk’s Jet Playbook—65°, Dim Lights, No Vents—And Full Throttle, Always [Roundup]](https://viewfromthewing.com/wp-content/uploads/2017/07/20170726_084344.jpg?#)

![‘I’ve Got 8 Chickens at Home Counting on Me’—Delta Pilot Calms Nervous Cabin With Bizarre Safety Promise [Roundup]](https://viewfromthewing.com/wp-content/uploads/2025/04/delta-cabin.jpg?#)