Boltaron slashes tray table weight, offers more recycled materials

HAMBURG — One of the most fascinating aspects of the yearly Aircraft Interiors Expo is that it includes practically the entire supply chain, from airlines to airframers, seatmakers and IFEC suppliers, all the way through to carpet designers and thermoformed plastic sheet manufacturers like SIMONA Boltaron, based in the marvellously named Newcomerstown, Ohio. Sitting down with the... The post Boltaron slashes tray table weight, offers more recycled materials appeared first on Runway Girl.

HAMBURG — One of the most fascinating aspects of the yearly Aircraft Interiors Expo is that it includes practically the entire supply chain, from airlines to airframers, seatmakers and IFEC suppliers, all the way through to carpet designers and thermoformed plastic sheet manufacturers like SIMONA Boltaron, based in the marvellously named Newcomerstown, Ohio.

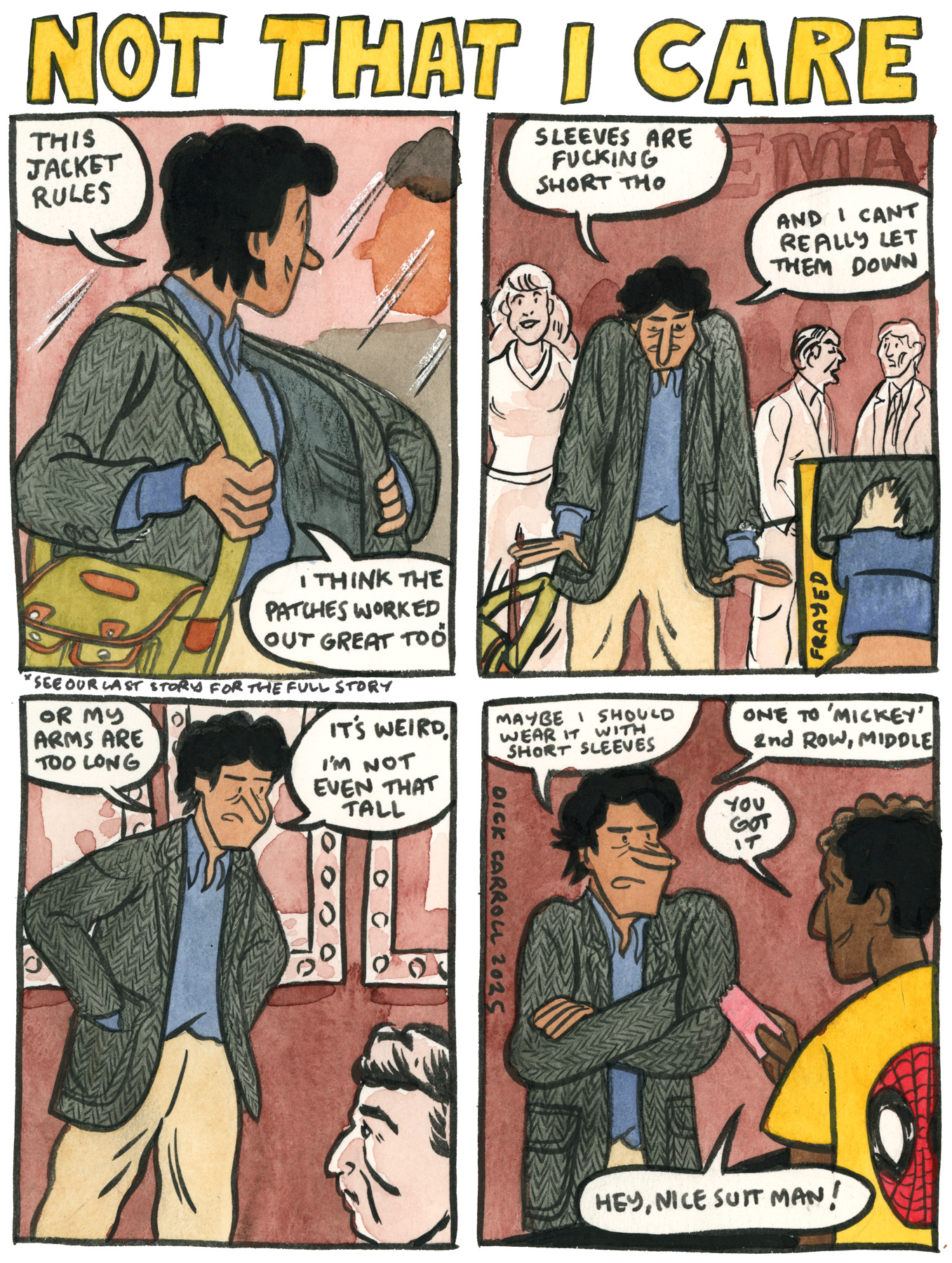

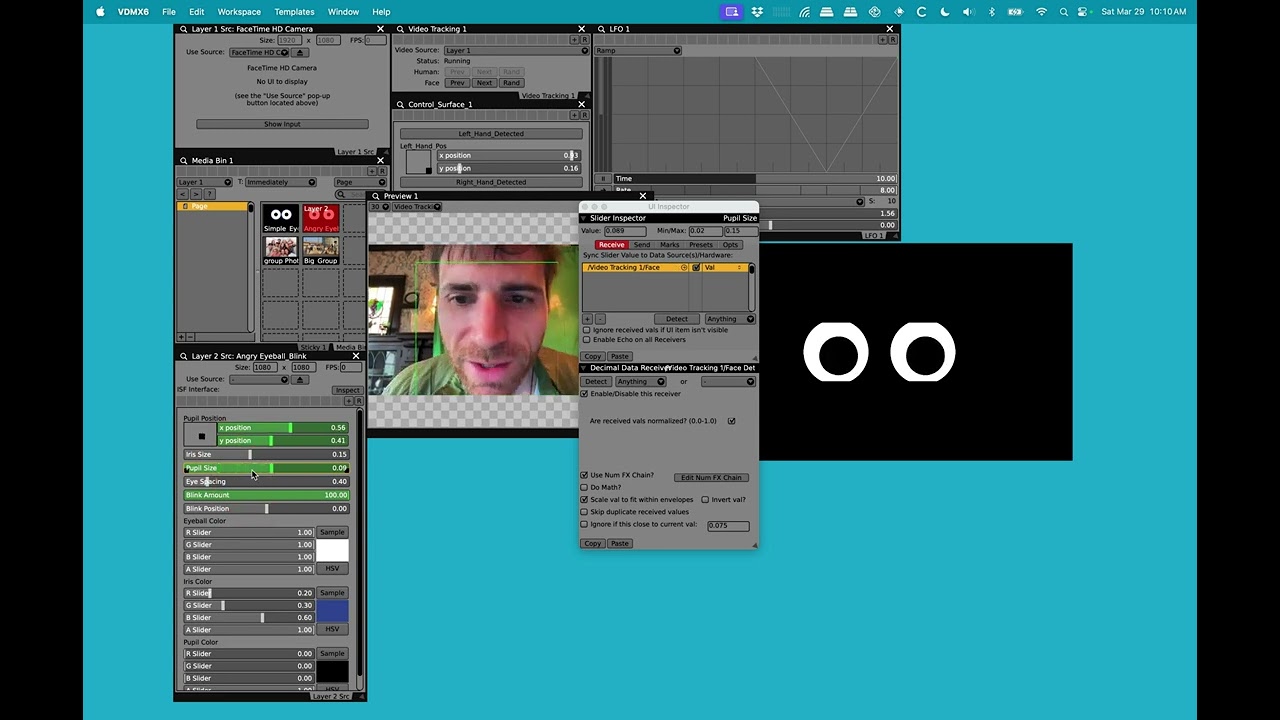

Sitting down with the team at AIX — and, indeed, standing up in order to experience their live online virtual reality seat design collaboration tool on an Apple Vision Pro headset — the improvements not just in Boltaron’s fundamental products aboard the aircraft cabin but to the way that the company is working with other parts of the industry were clear. Interiors suppliers are keen to be involved as early as possible, and as much as possible, with the design and certification process, and are using all the tools at their disposal to do so, wherever their manufacturing locations happen to be.

Perhaps Boltaron’s most eyecatching innovation in numbers terms is a new lighter plastic that the company’s AIX stand proclaims as “ideal for tray tables”, Boltaron 4380, certified for FAR 25.853 (a), often referred to as “Paragraph A” in this context. 4380 succeeds predecessor material 4330 but offers an 8 percent weight reduction with a 17.2°F higher heat distortion temperature.

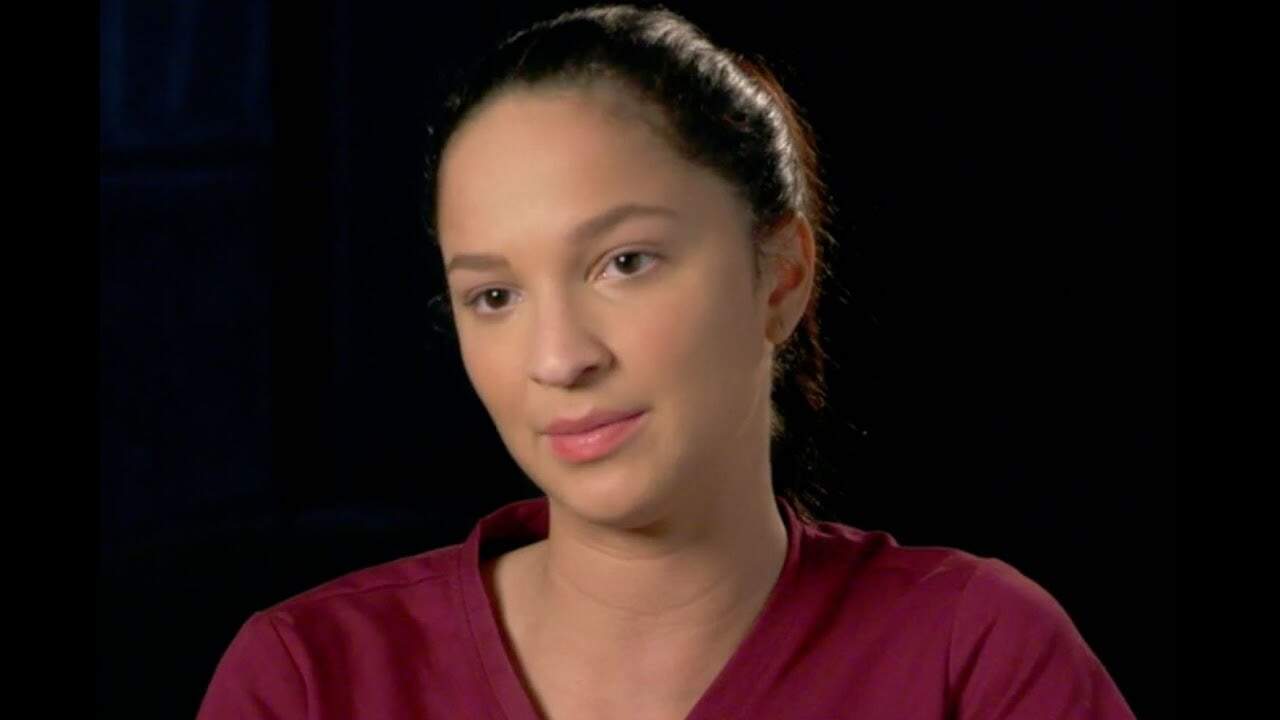

These improvements, marketing manager Valerie Glover tells RGN, come from a different blend of materials and different processing techniques.

Glover explains that 4380 “meets paragraph A, so it could be used for those smaller parts, like tray tables or some of those more hidden parts and components. When you multiply that over thousands of parts, you really can continue to contribute to a big [reduction in] carbon footprint.”

An 8 percent reduction on a single like-for-like component swap is impressive in the aviation context, where an aircraft re-engining adds around 15-20 percent in efficiency terms and the most advanced winglets might offer a 4-5 percent improvement.

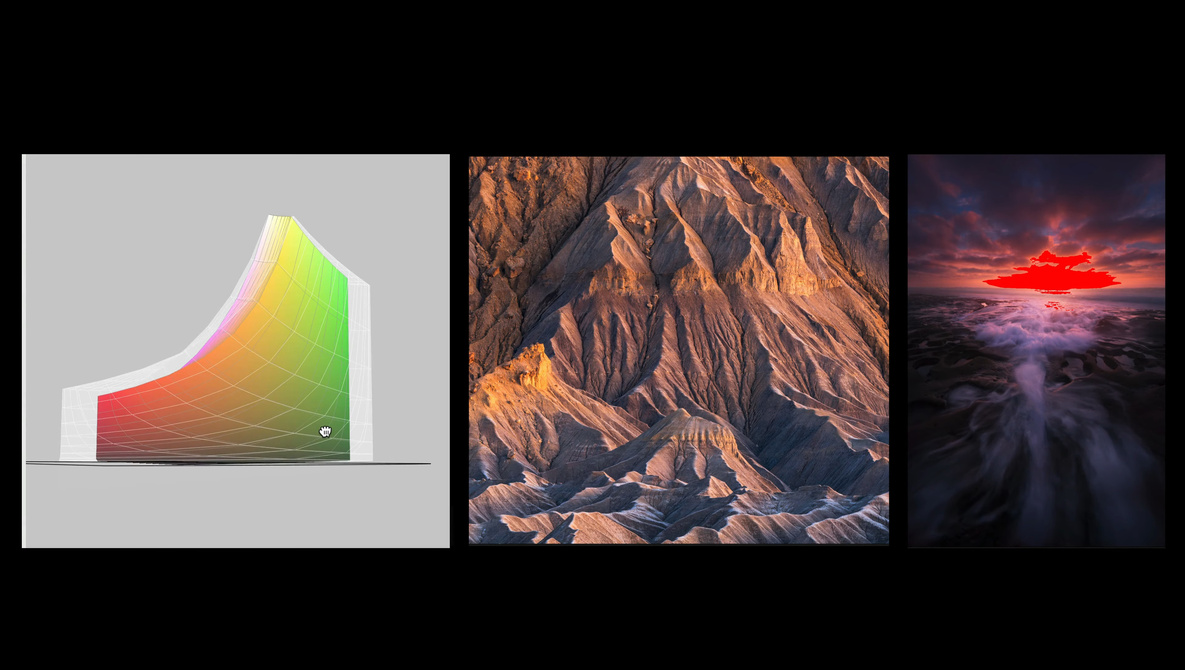

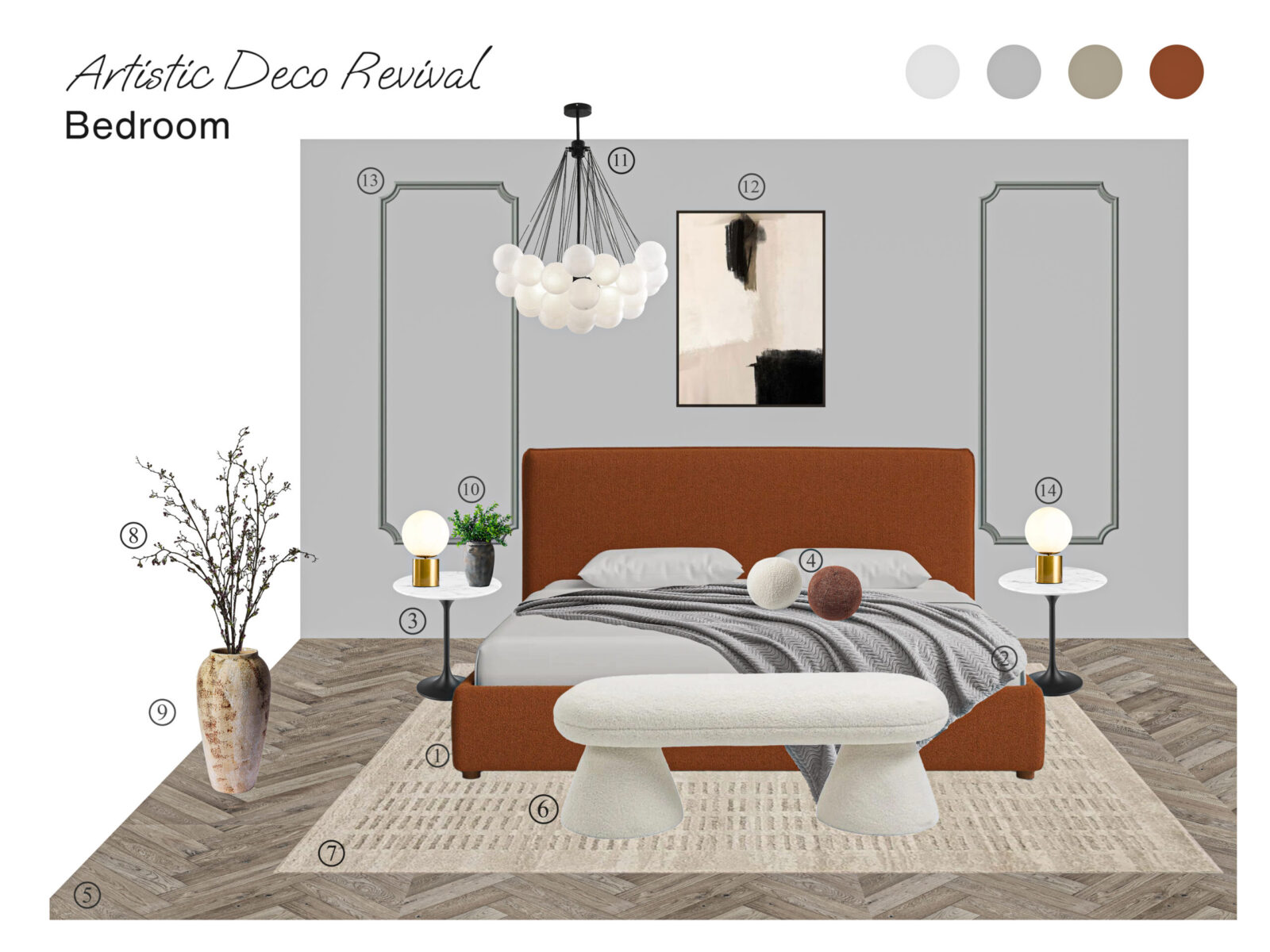

Boltaron is also expanding its Terreform range of materials, which include from 50-100 percent recycled materials. There now total 22 colour options — from beiges and greys through reds, blues, greens in pastel to medium saturation levels.

Where customers order samples of non-recycled materials for which Terreform is a strong replacement candidate, Boltaron is now including a small card introducing the range.

“We can design your more standard materials that you’re used to with these more sustainable options, we have lighter weight options, we have options that have 50% up to 100% recycled content,” Glover explains. “We’ve done the calculations — so it’s a 50% carbon footprint savings when you’re looking at 100% recycled content material, versus at the 50% recycled content, you’re looking at a 25% carbon footprint savings.

“We’re just letting customers know that if you do intend to be sustainable, we do have those options, but there may be an aesthetic tolerance that is not pristine perfection, and we can as an industry, I think be okay with that, and I think passengers will be okay with that. It just needs to be communicated.”

Here, Glover refers to the small inclusions, minor colour variations and other imperfections that are inherent to any material with a substantial amount of recycled content, and with which consumers are becoming increasingly familiar. It is, essentially, the aviation equivalent of a recycled soft drink bottle being a slightly different shade than its non-recycled equivalent when examined close up.

Given that Terreform can be used for elements ranging from instrument panel housings to seat parts, dividers, monuments, sidewalls, galleys and lavatories, there will be many applications where this aesthetic imperfection will be largely irrelevant, but even on direct passenger-facing elements it’s likely that the increasingly environmental consciousness among travellers means airlines should face few obstacles in using the material. After all, no plastic element in the cabin is pristine for longer than its first couple of flights.

- SIMONA Boltaron ensures material traceability in sustainability push

- Collaboration brings Boltaron translucents to life on JAL A350

- Acro CEO on why Series 9 recyclability is only the beginning

- How SIMONA is embracing sustainability at every rung of its business

All images credited to Boltaron

The post Boltaron slashes tray table weight, offers more recycled materials appeared first on Runway Girl.

![‘Haruki Murakami Manga Stories Vol. 3’ Gives Foreboding Fiction a Macabre Makeover [Review]](https://i0.wp.com/bloody-disgusting.com/wp-content/uploads/2025/04/Haruki-Murakami-Manga-Stories-Vol-3-Car-Attack.jpg?fit=1400%2C700&ssl=1)

.png?format=1500w#)

![THE NUN [LA RELIGIEUSE]](https://www.jonathanrosenbaum.net/wp-content/uploads/2019/12/TheNun-300x202.jpg)

![Courtyard Marriott Wants You To Tip Using a QR Code—Because It Means They Can Pay Workers Less [Roundup]](https://viewfromthewing.com/wp-content/uploads/2025/04/tipping-qr-code.jpg?#)