Japan's "Swap Reefer" Trucks with Freestanding Detachable Cargo Containers

If you hear the term "Reefer Truck," you might think it has something to do with weed. But that's the colloquial term used in Japan for refrigerated ("reefer") cargo trucks.Vehicle manufacturer Nippon Trex Co. learned of a problem faced by their clients in the cold-chain cargo business: Not enough drivers, not enough trucks. They thus designed this Swap Reefer truck, which features a long cargo-carrying chassis and has a special trailer that can be detached and stands on its own legs. This has several advantages. Typically, a reefer truck driver shows up to the loading point. The cold cargo, which might be perishables or pharmaceuticals, is loaded as the driver waits. During the loading process, the temperature of the refrigerated cargo cabin naturally drops. Once everything's loaded and the container is sealed again, the driver must wait for the cargo cabin to work its way back down to temperature before they can leave.Once they get to the destination, the driver must of course wait for the truck to be unloaded.The Swap Reefer is a far better system. The cargo container is loaded and set to temperature beforehand, so all the driver does is show up, then attach it. At the destination, they detach the trailer and don't need to wait for the unloading; instead they can take off to do another job. Furthermore, if it's a long haul, the cargo container can be carried there by multiple short-haul drivers, relay-style.I've cued up the video below so you can see how the trailers are detached. It looks pretty straightforward:I'm glad they solved the problem using a physical solution and human drivers, rather than focusing on autonomous trucks.

If you hear the term "Reefer Truck," you might think it has something to do with weed. But that's the colloquial term used in Japan for refrigerated ("reefer") cargo trucks.

Vehicle manufacturer Nippon Trex Co. learned of a problem faced by their clients in the cold-chain cargo business: Not enough drivers, not enough trucks. They thus designed this Swap Reefer truck, which features a long cargo-carrying chassis and has a special trailer that can be detached and stands on its own legs.

This has several advantages. Typically, a reefer truck driver shows up to the loading point. The cold cargo, which might be perishables or pharmaceuticals, is loaded as the driver waits. During the loading process, the temperature of the refrigerated cargo cabin naturally drops. Once everything's loaded and the container is sealed again, the driver must wait for the cargo cabin to work its way back down to temperature before they can leave.

Once they get to the destination, the driver must of course wait for the truck to be unloaded.

The Swap Reefer is a far better system. The cargo container is loaded and set to temperature beforehand, so all the driver does is show up, then attach it.

At the destination, they detach the trailer and don't need to wait for the unloading; instead they can take off to do another job.

Furthermore, if it's a long haul, the cargo container can be carried there by multiple short-haul drivers, relay-style.

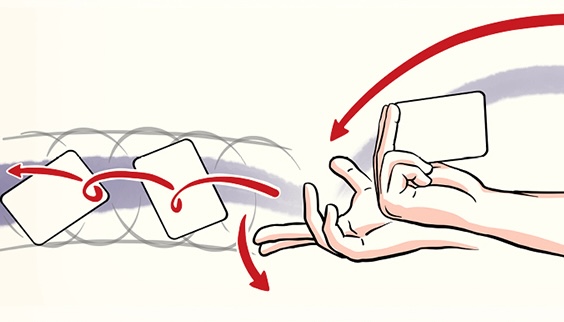

I've cued up the video below so you can see how the trailers are detached. It looks pretty straightforward:

I'm glad they solved the problem using a physical solution and human drivers, rather than focusing on autonomous trucks.

![‘Zombie Army VR’ Shuffles to a May 22 Release; Pre-Orders Open Now [Trailer]](https://bloody-disgusting.com/wp-content/uploads/2025/03/zombiearmy.jpg)

![Tubi’s ‘Ex Door Neighbor’ Cleverly Plays on Expectations [Review]](https://bloody-disgusting.com/wp-content/uploads/2025/03/Ex-Door-Neighbor-2025.jpeg)

![Uncovering the True Villains of Gore Verbinski’s ‘The Ring’ [The Lady Killers Podcast]](https://bloody-disgusting.com/wp-content/uploads/2025/03/Screenshot-2025-03-27-at-8.00.32-AM.png)

![Time-Tasting Places in 3 Current Releases [THE POWER OF THE DOG, PASSING, NO TIME TO DIE]](https://jonathanrosenbaum.net/wp-content/uploads/2021/11/000thepowerofthedog-1024x576.png)

.png?#)